You probably heard that digitizing your process was more affordable than working with traditional methods. But do you know the real cost difference between the two? TechMed 3D got you covered! We created several calculation tools to help you compare digital method costs to traditional method costs.

Read this article to learn how these calculation tools work.

Enter your personnal details

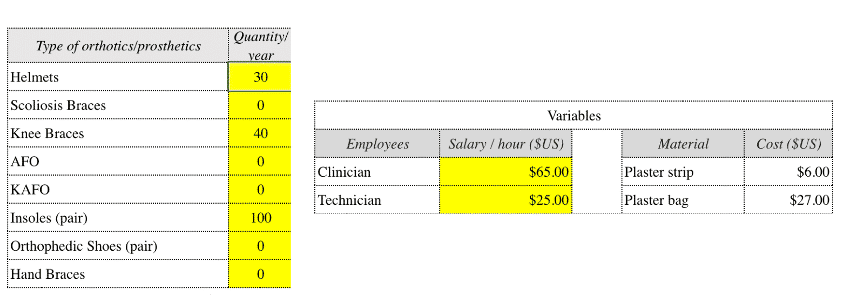

First, enter the details regarding the devices you produce each year and the salary of the employees needed to produce your devices. This step is very important as all the calculations will be based on that information. Moreover, this will allow you to see the exact pricing comparison regarding your production volume. In this example, we used a production volume of 30 helmets, 40 knee braces and 100 pairs of insole per year. Also, the hourly rate was set to 65$ for a clinician and 25$ for a technician.

Data comparison between traditional and digital methods

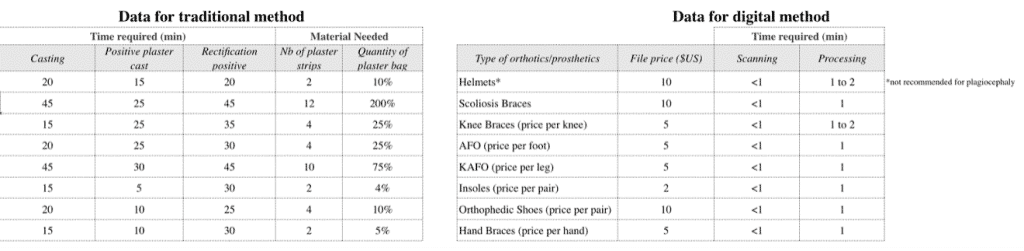

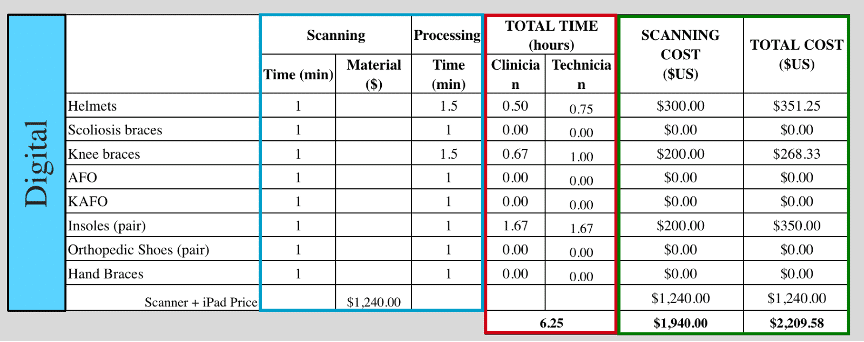

As you know, there are many steps involved when creating a full custom device. In these tables, we compared all the steps needed to create a device using a traditional method and all the steps needed to create a device using a digital method ( echMed’s solutions). As you can see, for the same result (i.e. to obtain the patient’s cast to produce a device) it requires a lot more steps and time when using a traditional method. To complete your costs evaluation, the tool will use these numbers, multiplied by your personal data previously filled in to calculate the cost difference.

Cost of your production with traditional and digital methods

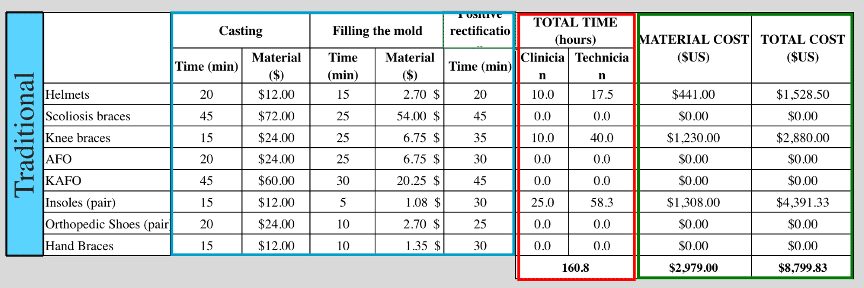

The last section of the tool is a breakdown of your production costs. In the blue section, you can find the material costs for each production steps as well as the time needed to complete the steps. Note that it varies from one device type to another. In the red section, you can find the time required per employee to complete the steps, again it varies from one device type to another. Finally, on the green section, you can see the totals. We wanted to separate the material/scanning costs and the total costs, since producing a device using digital methods allows you to save money for the material as well as the time needed.

When using TechMed 3D’s digital solutions, you will save time and money for your practice. Our pay per scan license model was designed for you to match your expense with your sales, meaning that you only spend the money you need to produce a device. Are you planning to digitize your production? Compare the real costs using the Einscan H, BodyScan and Structure Sensor calculation tools!

For more information, please contact our team.